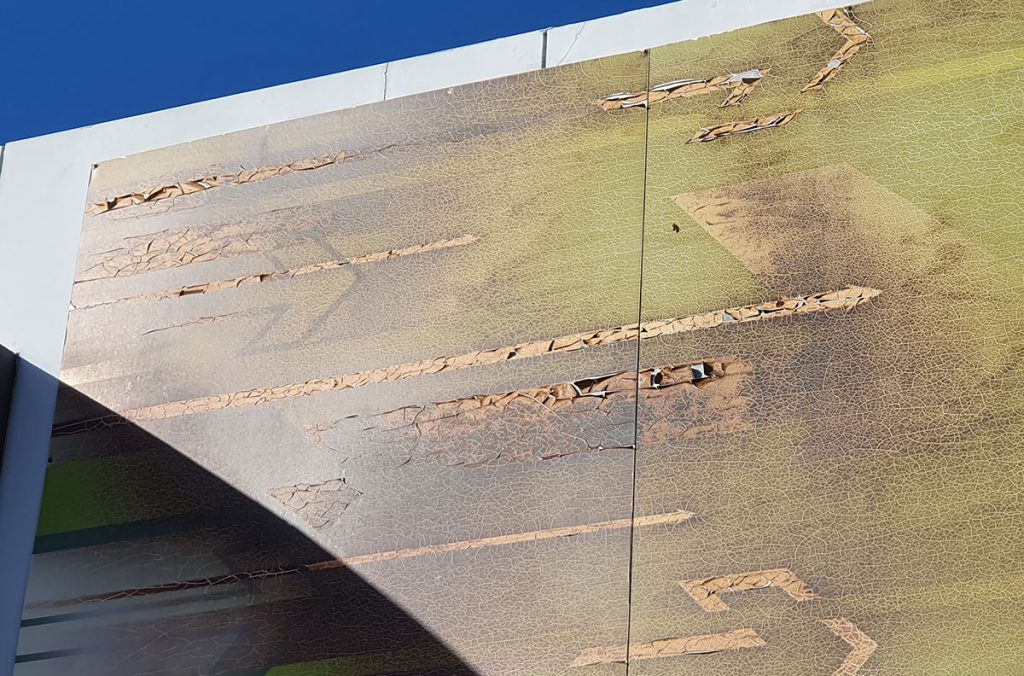

Often, when driving around, you’ll notice signs that have discoloured and some that look burnt.

You may see some signs that have turned brown, while others have lettering that has curled up at the edges.

This is a result of too much UV exposure.

But hang on – aren’t signs supposed to last out in the sun? Yes, they are.

So what’s the problem?

The wrong materials have been used.

A cheap sign means a cheap result

With signs, it’s all about the materials used.

Choose something high quality and you’ll get a beautiful long lasting sign.

Choose something cheap and the result will be exactly like the picture below.

The problem is when you get your shiny new sign, there’s no way of telling what the company has used to create it.

So, it’s worth being forearmed with some information before you order your sign, which is what we’ll go through below.

Cast versus calendered vinyls

Broadly speaking, there are two kinds of vinyls: cast and calendered.

They both have their purpose, however when they are first applied to your sign, they look exactly the same. So, what should you use?

The word “calendered” means extruded, so the vinyl is basically one big block of PVC that gets stretched out through rollers to create a cheap roll of vinyl.

Special oils called plasticisers are added to make the PVC more flexible, and it’s these oils which can create issues later on. We’ll get to that in a moment.

The word “cast” says exactly what it is – the PVC is poured out onto a mould, so it is cast in that shape.

Cast vinyls are thinner, have better quality plasticisers, more UV inhibitors and aren’t stretched to shape. This means that they will not shrink over time.

Check out the photo above – see the edges have shrunk and curled up? That’s a dead giveaway that a calendered vinyl was used.

In this case, it should have been a cast vinyl, so that it lasts.

As the vinyl degrades, the plasticiser leaches out of a calendered vinyl and it loses its flexibility. It wants to go back to its original shape, which is why it shrinks back and curls up.

Not a great result.

Key lesson: Unless your sign is only up for a few months, always request cast vinyl.

Use the right overlaminate

The laminate that goes over the sign is just as important as the surface that the inks are going onto.

That’s because the overlaminate is the first point of contact for UV before it gets to the sign face.

So, this clear layer has to ward off as much UV as possible to prevent the sign from being damaged and burned by the sun.

Again, you can use a cast laminate or a calendered laminate, however there are some better options available.

For a little more in cost, you can opt for a polyurethane overlaminate.

Polyurethane contains more UV inhibitors and because it isn’t a PVC, it doesn’t have the problem of plasticisers leaching out of the surface when it gets older.

There’s also another option: PVDF. Sometimes called “Tedlar”, this is a highly durable laminate that resists UV and chemicals far better than other laminates.

It’s only suitable for flat surfaces and works best on metal signs.

Of course, because it’s so good at resisting chemicals, it’s also used as an anti-graffiti film, but it does cost a bit more.

Key lesson: Your laminate should be a cast, polyurethane or PVDF film. Do not settle for cheaper laminates.

Inks are important, too

It goes without saying that UV stable inks need to be used. Don’t use aqueous inks (from a water-based printer).

Instead, UV curable, solvent or latex inks should be your only options. Most sign shops have one of those three, so it’s worth checking which they will be using.

Prevention is better than the cure

Can you fix a sign that’s already burned? Sadly, if it looks like the sign above, then there’s no fix.

However, if your sign has started to go yellow at the edges of lettering or you can see the colour changing slightly, then a wash and a polish with automotive grade polish will certainly help.

It may not bring it back to new, but it will certainly help sustain it and give it some more life to last a bit longer.

The best thing is to make sure the right vinyl, ink and laminate is used before you receive your sign. If necessary, check with your sign-shop’s supplier to make sure you’re getting the best quality result.

Of course, here at Perth Graphics Centre, we’re all about transparency, so you’re welcome to come into our workshop and find out for yourself what we’re using on your sign.

That’s why we’re Perth’s most trusted sign company.